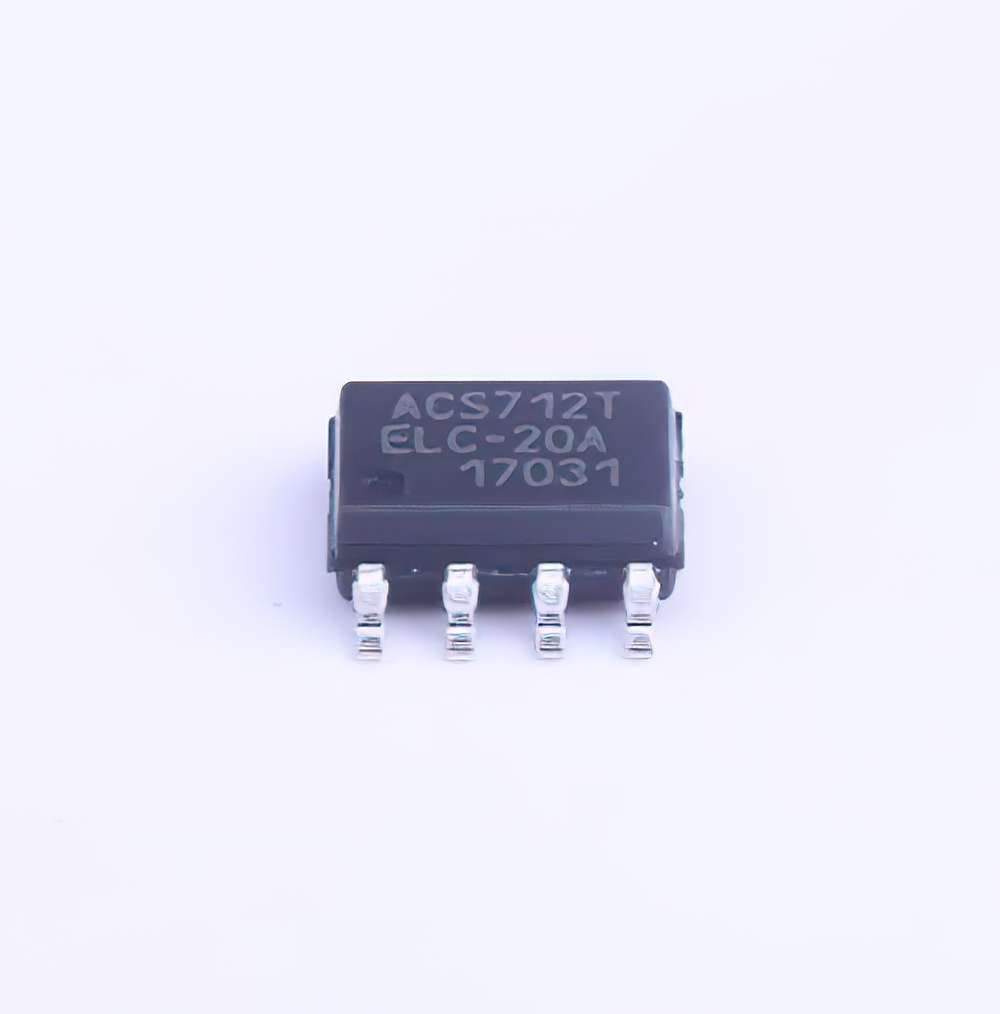

The ACS712ELCTR-20A-T is a widely used current Sensor that offers accurate current measurements for a range of applications. However, like any electronic component, it may experience issues during operation. This article discusses the most common troubleshooting techniques and solutions for the ACS712ELCTR-20A-T to help users maintain and optimize its performance.

ACS712ELCTR-20A-T, troubleshooting, current sensor, electronic components, current measurement, sensor issues, electronics troubleshooting

Understanding the ACS712ELCTR-20A-T and Common Issues

The ACS712ELCTR-20A-T is a Hall-effect-based current sensor that can measure both AC and DC currents. With a wide operating range of up to 20A, it is suitable for a variety of Power monitoring applications, ranging from power supplies and motor drivers to home energy meters. However, users occasionally face issues such as incorrect readings, low accuracy, or lack of response from the sensor. Identifying and solving these problems is essential to ensure that the sensor operates effectively in your circuit.

1. Incorrect Output Voltage

One of the most common issues with the ACS712ELCTR-20A-T is receiving incorrect output voltage readings. Since the sensor outputs an analog voltage proportional to the current flowing through it, users may find that the voltage readings do not match the expected values.

Possible Causes:

Power Supply Issues: The ACS712 operates from a 5V supply (typically). If the supply voltage deviates significantly from this value, it could affect the accuracy of the sensor’s output.

Improper Grounding: The sensor’s ground pin should be properly connected to the system’s common ground. If there is a floating ground or improper connection, the output voltage will be unreliable.

Faulty Wiring or Connections: Loose wires or poor soldering on the sensor's pins can result in fluctuating or incorrect output voltage.

Solutions:

Check Power Supply: Ensure that the sensor is powered by a stable 5V supply. Measure the voltage across the sensor's power pins to confirm that it is within the acceptable range.

Verify Grounding: Ensure that the ground pin of the ACS712 is securely connected to the system's ground. A poor ground connection can lead to noise and instability in the output.

Inspect Connections: Examine all the wiring and soldering connections for any signs of damage, poor solder joints, or loose wires. A solid connection is crucial for accurate performance.

2. Offset Voltage Issues

Another issue that users may encounter is an unexpected offset in the sensor's output when no current is flowing through it. The ACS712 is designed to output a voltage of approximately 2.5V when there is no current flow (0A), but this baseline can sometimes drift, causing measurement errors.

Possible Causes:

Environmental Factors: Temperature variations or electromagnetic interference ( EMI ) from nearby equipment can affect the sensor’s baseline output.

Sensor Defects: In some rare cases, the sensor itself may have internal issues, such as a faulty Hall sensor or calibration drift.

Solutions:

Zero-Current Calibration: Perform a zero-current calibration by reading the output voltage of the sensor when no current is flowing. If the reading is significantly different from 2.5V, apply an offset correction in the software to account for this discrepancy.

Shielding and Noise Reduction: If electromagnetic interference is suspected, use shielding materials or add decoupling capacitor s near the sensor to reduce noise. Proper layout design can also help minimize the impact of EMI.

3. Overload and Damage Protection

The ACS712 is designed to handle currents up to 20A, but applying excessive current can permanently damage the sensor. If you notice that the sensor’s output is saturated (stuck at a high or low voltage), or if there is visible damage to the sensor, it may have been exposed to a current beyond its rating.

Possible Causes:

Exceeding Current Rating: The sensor can only handle up to 20A, and exposing it to higher currents will damage the internal circuitry.

Power Surge or Spike: Sudden power spikes or surges can cause damage to the sensor even if the continuous current does not exceed the limit.

Solutions:

Implement Overcurrent Protection: Use a current-limiting circuit or fuse in your application to ensure that the current passing through the sensor does not exceed its rating.

Use a Different Sensor for Higher Currents: If your application consistently involves currents higher than 20A, consider switching to a sensor with a higher current range, such as the ACS758, which can measure up to 50A.

Advanced Troubleshooting and Optimizing ACS712ELCTR-20A-T

While the basic troubleshooting steps are helpful for identifying common issues with the ACS712, there are some advanced strategies that can further enhance the sensor’s performance and address more complex problems.

4. Linear Calibration and Accuracy Enhancement

Even though the ACS712 provides a linear output with a specified sensitivity (185mV per 10A), slight deviations in the sensor’s output can still occur due to manufacturing variances, environmental conditions, or long-term drift. For applications that require high accuracy, additional calibration may be needed.

Possible Causes:

Manufacturing Tolerances: Small variations between sensors can cause slight differences in sensitivity and output characteristics.

Temperature Effects: The sensor’s output may change slightly with temperature variations, especially if the sensor operates in environments with fluctuating temperatures.

Solutions:

Perform Calibration in Software: To account for the sensor's inherent variance, calibrate the sensor using a known reference current. Take several readings at known currents, and use these measurements to adjust the output in software for greater accuracy.

Temperature Compensation: If temperature variations are significant in your application, consider adding temperature sensors to the circuit to dynamically adjust the output of the ACS712 based on the ambient temperature.

5. Handling Noise and Interference

The ACS712 is sensitive to noise and electromagnetic interference (EMI), especially in noisy environments. This can lead to erratic or unstable output readings. Noise is especially problematic in industrial applications or when working with motors, inductive loads, or high-frequency switching circuits.

Possible Causes:

Inductive Loads: Motors and relays generate high-frequency noise when switching on or off, which can interfere with the sensor’s readings.

Power Line Noise: The sensor can pick up noise from nearby high-power circuits, especially if it is placed close to switching power supplies or large loads.

Solutions:

Use Filtering Techniques: Add decoupling capacitors (e.g., 0.1µF ceramic) near the power pins of the ACS712 to filter high-frequency noise. Low-pass filters can also be added to the output signal to smooth out the readings.

Shielding: Use shielding materials or enclosures to isolate the sensor from external electromagnetic sources. Proper PCB layout, with separate ground planes and short signal traces, can help reduce the impact of noise.

Twisted-Pair Wires: For the current-carrying conductors, use twisted-pair wires to minimize the electromagnetic field that might induce noise in the sensor.

6. Software Solutions for Better Data Handling

To further improve the performance of the ACS712 and handle potential issues in data processing, consider incorporating software-based solutions into your system.

Possible Solutions:

Averaging Multiple Samples: Noise and minor fluctuations can often be reduced by taking multiple readings over a short period and averaging them. This technique is particularly useful when measuring small currents or when the sensor is in a noisy environment.

Dynamic Range Adjustment: For applications where the current fluctuates over a wide range, use dynamic range scaling to adjust the measurement resolution depending on the current level. This can ensure accurate readings across the full range of the sensor.

7. Replacing a Faulty ACS712 Sensor

If the troubleshooting steps outlined above do not resolve the issue, or if the sensor appears to be damaged beyond repair, replacing the sensor may be necessary.

Solution:

Replace the Sensor: In cases where the sensor is no longer functioning correctly, replacing the ACS712 with a new one is the most straightforward solution. Ensure that the new sensor is compatible with your circuit and specifications.

By understanding these common troubleshooting tips and solutions, users can ensure that their ACS712ELCTR-20A-T current sensor remains reliable and accurate in various applications. Whether dealing with wiring issues, calibration adjustments, or mitigating interference, each problem can be addressed systematically, ensuring that your power monitoring setup operates smoothly.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.