Introduction to Overcurrent Protection and FPF2700MPX

Overcurrent protection is an essential aspect of designing reliable electronic circuits and systems. It safeguards devices from potential damage caused by excessive currents that could result from a variety of factors, such as short circuits, overloads, or Power surges. When current exceeds the design threshold, it can cause overheating, component failure, or even fire hazards. Thus, ensuring that electrical circuits remain within safe operating conditions is critical for the longevity and safety of electronic devices.

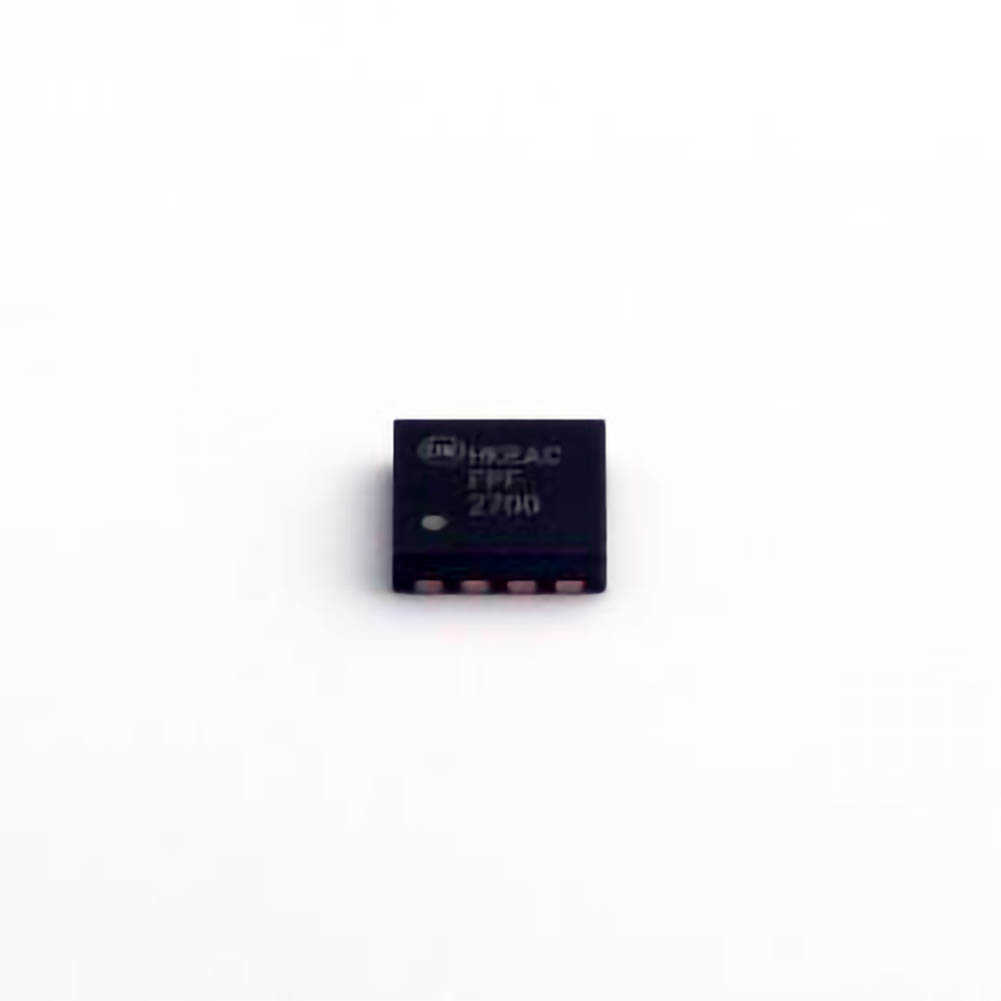

Overcurrent protection circuits have evolved significantly over the years, with advances in semiconductor technology playing a central role. One such breakthrough component that has gained popularity for use in these circuits is the FPF2700MPX, a current limiting power switch with a variety of features that make it an ideal choice for modern overcurrent protection applications.

This article will delve into the application and design schemes involving the FPF2700MPX in overcurrent protection circuits, highlighting its functions, advantages, and key design considerations for engineers.

The Need for Overcurrent Protection

Overcurrent protection is a fundamental requirement in both low and high-power applications. Devices such as power supplies, battery chargers, Motor Drivers , and sensitive electronic circuits can be vulnerable to damage when subjected to excessive current flow. Overcurrent can occur due to a variety of reasons:

Load Variations: Unexpected changes in load can cause a surge in current.

Fault Conditions: A short circuit or ground fault can lead to an instantaneous rise in current.

External Interference: Transient voltage spikes or electromagnetic interference can create short bursts of high current.

Power Surges: Sudden increases in voltage due to lightning strikes or switching operations.

Without proper overcurrent protection, electronic devices may suffer from permanent damage, leading to expensive repairs or system downtime.

FPF2700MPX: A Solution for Overcurrent Protection

The FPF2700MPX is an advanced power switch designed to provide robust current limiting and overcurrent protection. Manufactured by ON Semiconductor, it is primarily used for high-speed switching applications where precise control over current flow is critical. The device integrates several key features that make it highly effective in preventing damage due to overcurrent scenarios.

Key Features of FPF2700MPX:

Current Limiting: The FPF2700MPX provides a built-in mechanism to limit the output current to safe levels, thus preventing circuit damage from overcurrent events.

Thermal Shutdown: In case of excessive temperature rise due to overcurrent, the device automatically shuts down to protect both the component and the circuit.

Low Rds(on): With a low on-resistance (Rds(on)), it minimizes voltage drop and power dissipation, making it highly efficient in protecting circuits without affecting overall performance.

Overvoltage Protection: The FPF2700MPX is equipped with overvoltage protection to safeguard against power surges and transients.

Overcurrent Detection: It continuously monitors current flow and can quickly detect and respond to current levels that exceed safe operating limits.

Fast Response Time: The device responds rapidly to fault conditions, ensuring that protection is activated before damage occurs to sensitive components.

These attributes make the FPF2700MPX an ideal solution for a wide range of overcurrent protection applications, from low-power consumer electronics to industrial-grade systems.

Typical Applications of FPF2700MPX

The versatility of the FPF2700MPX makes it suitable for use in various fields. Some of its key applications include:

Power Supply Circuits: Overcurrent protection in power supplies is crucial to prevent power delivery failures or excessive heating.

Battery Charging Circuits: The device can protect batteries from overcurrent, ensuring that charging cycles remain within safe limits.

Motor Drivers : Motors, especially in industrial and automotive applications, can draw high currents. The FPF2700MPX can limit current flow to protect both the motor and the drive electronics.

Consumer Electronics: In smartphones, laptops, and other consumer devices, overcurrent protection ensures the longevity of internal components, especially when dealing with volatile loads.

Automotive Circuits: In automotive applications, the FPF2700MPX ensures that electronic control systems are protected from current spikes, especially in environments with fluctuating power supply conditions.

How FPF2700MPX Works in Overcurrent Protection

The operation of the FPF2700MPX in overcurrent protection circuits is based on its ability to monitor and control current flow. Under normal conditions, the device allows current to pass through with minimal resistance, ensuring the smooth operation of the circuit. However, if the current exceeds a predefined threshold, the FPF2700MPX enters a protective mode:

Current Limiting Mode: The device dynamically reduces the output current by limiting the current flow. This prevents damage to downstream components by ensuring the current does not exceed safe levels.

Thermal Shutdown: If the device detects an unsafe temperature due to prolonged high current or short-circuit conditions, it automatically shuts down to prevent overheating. This helps prevent damage to both the FPF2700MPX and surrounding components.

Automatic Recovery: Once the fault condition is cleared, the FPF2700MPX can automatically resume normal operation, ensuring minimal downtime and maintaining system stability.

Design Considerations When Integrating FPF2700MPX into Overcurrent Protection Circuits

When designing circuits with the FPF2700MPX, engineers must take into account various factors that will ensure optimal protection and reliability. Some key design considerations include:

Current Thresholds: The FPF2700MPX comes with a configurable current threshold, allowing engineers to tailor the protection to specific applications. Careful selection of the threshold ensures the device reacts promptly to faults without unnecessary interruptions during normal operation.

Thermal Management : While the FPF2700MPX offers thermal shutdown protection, engineers must still ensure that the device operates within its specified thermal limits. Adequate heat sinking, PCB layout optimization, and good ventilation are crucial for maintaining reliable performance.

Inductive Load Considerations: When working with inductive loads, such as motors or solenoids, engineers should account for back EMF (electromotive force) and ensure that the FPF2700MPX’s overvoltage protection features are properly engaged.

PCB Design: Proper layout and routing of power and signal paths on the PCB are essential for minimizing parasitic inductance and ensuring that the device responds promptly to overcurrent events.

Advanced Design Schemes Using FPF2700MPX in Overcurrent Protection Circuits

As electronic devices become more complex, the demands on protection circuits have increased. In response, advanced design schemes are necessary to provide effective protection while maintaining efficiency, reliability, and compactness. In this section, we will explore advanced design strategies using the FPF2700MPX in overcurrent protection circuits, focusing on system integration, fault detection, and optimization.

Integration of FPF2700MPX into Power Management Systems

In power management systems, the FPF2700MPX can play a central role in ensuring that voltage and current levels remain within safe limits. By integrating the device into the power distribution network, designers can create comprehensive protection systems that manage power flow efficiently.

Example Circuit Design:

Consider a power supply that provides 5V to various components in a system. The design can integrate the FPF2700MPX between the power supply and the load, as shown below:

Input Stage: The power supply delivers 5V to the FPF2700MPX, which monitors the current passing to the load.

Current Monitoring: The device continuously compares the current with a predefined threshold. If the current exceeds this threshold due to a short circuit or overcurrent condition, the device enters protection mode.

Output Control: The FPF2700MPX either limits the current flow or shuts down to prevent damage, ensuring the connected load remains protected.

By placing the device at the critical juncture of the power supply, the system benefits from real-time current protection, ensuring both the supply and load are safeguarded from damage.

Fault Detection and Rapid Response

One of the significant advantages of the FPF2700MPX is its rapid response time to overcurrent conditions. In high-speed systems, such as communications equipment, automotive electronics, or industrial machines, quick fault detection is crucial to minimizing system downtime and preventing cascading failures.

Fault Detection Mechanism:

The FPF2700MPX features advanced fault detection algorithms that constantly monitor current flow. In the event of an overcurrent situation, the device immediately activates the protection mode. This response time is often in the range of microseconds, ensuring that components receive instantaneous protection.

Moreover, the FPF2700MPX’s ability to distinguish between transient spikes and sustained overcurrent events allows the circuit to remain operational during minor disturbances, further enhancing reliability.

High-Efficiency Design

In modern electronic systems, power efficiency is a top priority. The FPF2700MPX stands out due to its low on-resistance (Rds(on)), which minimizes power dissipation. Even under heavy loads or high currents, the device ensures that only a minimal voltage drop occurs, improving overall efficiency.

Efficiency Optimization:

When designing with the FPF2700MPX, engineers should focus on reducing parasitic losses, especially in high-current paths. Efficient PCB design practices, such as using wide copper traces, minimizing trace lengths, and implementing proper decoupling capacitor s, can further enhance the system’s overall power efficiency.

Multi-Stage Protection Schemes

For more advanced applications, engineers may need to implement multi-stage protection schemes. These systems combine several protection devices, such as fuses, circuit breakers, and the FPF2700MPX, to ensure the highest level of security.

Stage 1: Surge Protection: A surge protector or TVS diode can be placed at the input to clamp high-voltage spikes before they reach sensitive components.

Stage 2: Overcurrent Protection: The FPF2700MPX is placed at the output stage to provide current limiting and thermal protection.

Stage 3: Fail-Safe Mechanisms: In some designs, redundant systems such as backup fuses or secondary thermal sensors may be added to ensure continued protection in case of device failure.

This multi-layered approach ensures that protection is provided at various levels, minimizing the risk of catastrophic failures.

Conclusion

The FPF2700MPX is an invaluable tool in overcurrent protection circuits, offering a sophisticated, efficient, and reliable solution for safeguarding electronic systems. By integrating this power switch into modern designs, engineers can ensure that their systems are both resilient and optimized for long-term performance. Whether in consumer electronics, automotive applications, or industrial systems, the FPF2700MPX provides the necessary protection against overcurrent events, ensuring the reliability and safety of the devices it serves.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.